Innovation in Packaging: A Peek Into The World of The PET Sheet Suppliers

In the current busy industrial and consumption atmosphere, packaging is not simply about associating a product with a cover, but is a way of maintaining quality, ensuring safety, and making products and packaging friendly and sustainable. One key stakeholder in this revolution of packaging is the PET Sheet Manufacturers. Their new application of Polyethylene Terephthalate (PET) has enabled these manufacturers to assist industries in transforming their traditional sustainable and unsustainable materials into lightweight, strong, and recyclable ones.

The industry of packaging is shifting so fast, and PET Sheet Manufacturers have become the center of this change. PET sheets are also being used to make food-grade packaging, electronics casing, and industrial clamshells, to name a few, and they are demonstrating themselves to be the ideal, combining form and function.

Who Makes PET Sheets?

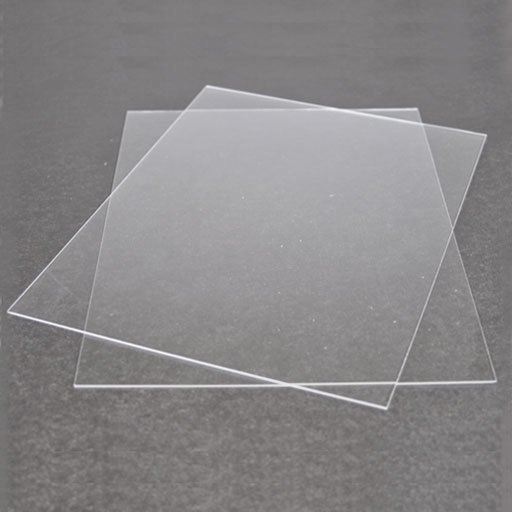

PET sheets also provide the optimal combination of strength, clarity, and sustainability, unlike other types of plastic materials. This qualifies them to be used in food containers, as well as medical trays. PET Sheet Manufacturers appear to be obsessively working on conditioning products that are of high levels of hygiene, safety, and environmental consideration, hence becoming a very significant intermediary component of the global supply chain.

As an example of how the market is influencing the choice of PET Sheet Manufacturers in India, the need to use transparent, recyclable, and heat-resistant packaging stimulates more industry players to collaborate with familiar entities. Such manufacturers are able to employ the latest extrusion technology in order to meet a constant thickness and clarity, knowing that super-critical retail packaging must not only be aesthetically pleasing but it must also functional.

Innovation is the nerve center of PET sheet manufacturers

The real advantage that PET Sheet Manufacturers have is innovation. Consumers are now demanding that their products be eco-friendly, and enterprises are responding with biodegradable mixtures, recycled PET (rPET), and light-weight forms that cut transportation costs without an adverse impact on the quality of the substance.

R&D teams within the leading PET Sheet Manufacturers are in the constant process of making improvements in barrier properties, carbon footprint, and sheets that can be reused or reprocessed. Such a commitment to finding new ways of doing things makes it possible to see businesses achieving global sustainability goals along with upping their efficiency and aesthetics.

The reasons why industries are using PET sheets instead of other materials

Food and beverage, pharmaceutical, electronics, and personal care industries are finding more and more reasons to call PET Sheet Manufacturers with their custom needs. PET sheets are more favoured because they are made of materials that are not susceptible to moisture, chemicals, and UV rays. The brands can also have a competitive advantage in the world, which is rapidly moving towards green solutions, because they are recyclable.

Most PET Sheet Manufacturers have sheets that are FDA and EU safety compliant, thus food-grade use is a common application. In addition, they are versatile in thermoforming, meaning that they can be molded in many different packaging forms without compromising the structure.

Sustainability as a factor in the evolution of PET sheet manufacturers in the future

The importance of sustainability is one of the most impressive changes in the packaging world. Manufacturers of PET Sheets are investing in sustainable manufacturing operations- they are using clean-energy sources such as solar energy, they minimize their waste products, and they recycle in-house scrap to create usable sheets.

There are also other processes underway wherein some manufacturers have released 100 percent rPET sheets produced and released entirely using post-consumer waste as part of the circular economy. Besides contributing to environmental objectives, this assists companies with meeting the changed regulations on the use of plastic.

This sustainable business is not a fad, but it is an extended agenda on the corporate responsibilities of a good PET Sheet Manufacturer.

The Problems that the PET sheet manufacturers experience

Despite all the booming, PET Sheet Manufacturers have their challenges: volatility in prices of raw materials; documents pertaining to green rules and regulations, etc. Nevertheless, they can be rather adaptable. There are a great number of companies that develop AI-based quality control schemes and automate production processes, and upskill their employees to reach top efficiencies and compete with others.

Such nimbleness enables PET Sheet Manufacturers to address the domestic and international demand, despite the supply chain disturbances, and makes them trusted partners in the packaging ecosystem.

Conclusion

PET Sheet Manufacturers is an unchallenged world that is filled with innovation, responsibility, and growth. With the increasing demand for sustainable and high-performance packages, companies are stretching. The companies are working towards the satisfaction of various worldwide demands. Their work helps make industries on all fronts of business, such as retail, healthcare, etc., to be able to use the materials that are not only efficient but also environmentally responsible

.

To the companies aspiring to remain on the cutting edge, there is no better moment to consider cooperation with progressive PET Sheet Manufacturers. The proper cooperation may present more intelligent packaging, enhanced brand image, and enhanced responsibility to the environment.